Innovative Applications of Best Fuel Filters in Diverse Industries

In an era where operational efficiency and environmental sustainability are paramount, the role of fuel filters in various industries cannot be overstated. Fuel filters are critical components that ensure the purity and efficiency of fuel in equipment and machinery, thus optimizing performance and prolonging lifespan. According to a recent report by MarketsandMarkets, the global fuel filter market is projected to reach USD 5.8 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth underscores the increasing demand for high-quality fuel filtration solutions across sectors such as automotive, aviation, and industrial manufacturing. As industries strive to meet regulatory standards and enhance fuel efficiency, innovative applications of fuel filters are becoming integral to operational strategies. This blog will explore the top strategies for leveraging the advancements in fuel filter technologies, showcasing their transformative impact on various industries.

In an era where operational efficiency and environmental sustainability are paramount, the role of fuel filters in various industries cannot be overstated. Fuel filters are critical components that ensure the purity and efficiency of fuel in equipment and machinery, thus optimizing performance and prolonging lifespan. According to a recent report by MarketsandMarkets, the global fuel filter market is projected to reach USD 5.8 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth underscores the increasing demand for high-quality fuel filtration solutions across sectors such as automotive, aviation, and industrial manufacturing. As industries strive to meet regulatory standards and enhance fuel efficiency, innovative applications of fuel filters are becoming integral to operational strategies. This blog will explore the top strategies for leveraging the advancements in fuel filter technologies, showcasing their transformative impact on various industries.

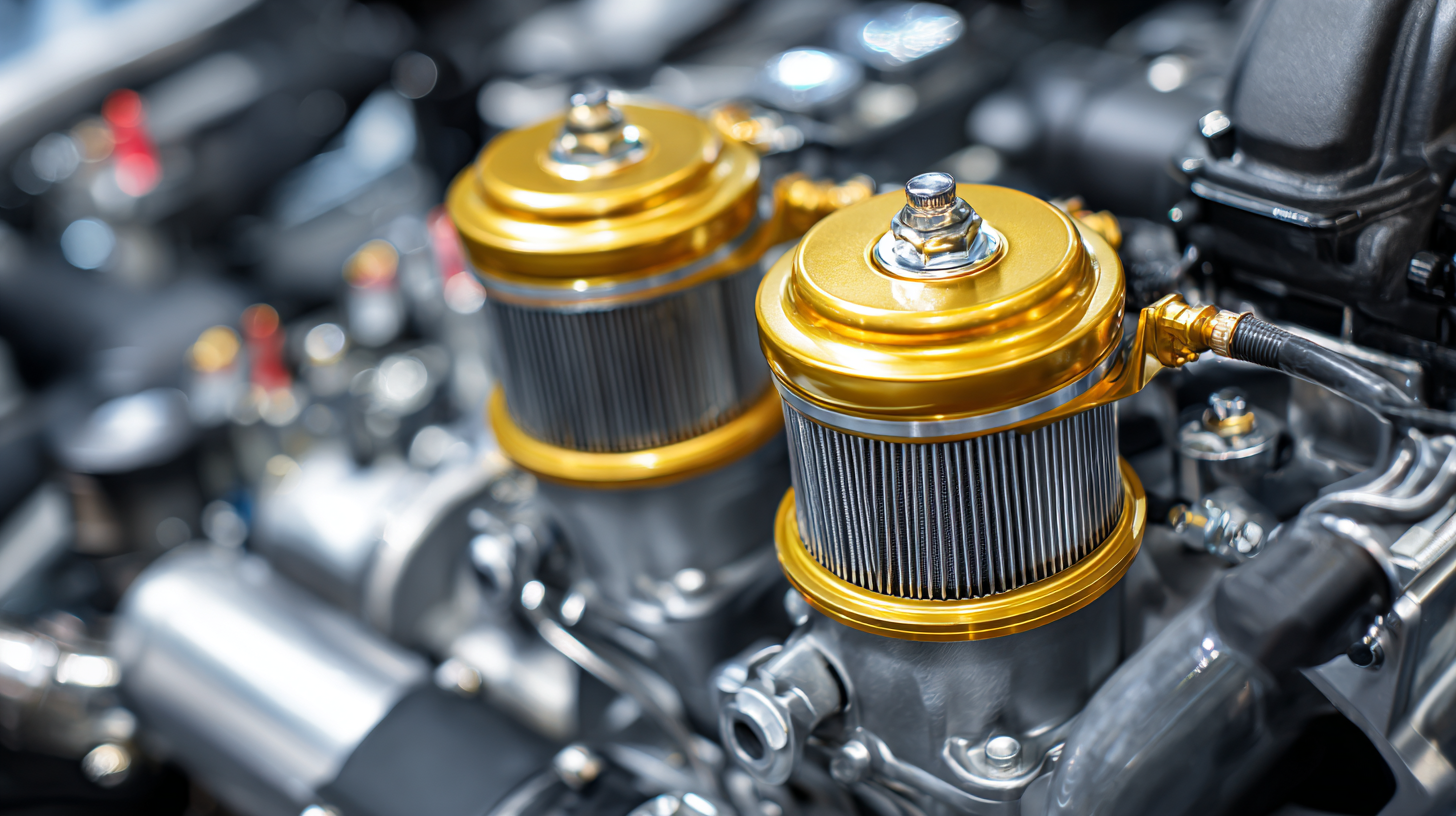

Innovative Fuel Filter Technologies Revolutionizing Automotive Sector

The automotive sector is undergoing a transformative shift, largely fueled by innovative fuel filter technologies that enhance engine performance and fuel efficiency. With the global automotive fuel filter market projected to reach $8.5 billion by 2026, as per a recent industry report, these advancements are critical in meeting the stringent emission regulations and consumer demand for cleaner vehicles. Modern fuel filters are designed not only to protect the engine but also to optimize fuel delivery, contributing to a reduction in harmful exhaust emissions by up to 30%.

One notable innovation is the use of advanced materials, such as synthetic fiber media, which offer superior dirt-holding capacity and filtration efficiency. This technology can lead to a longer service life, enabling vehicles to maintain optimal performance longer without an increase in maintenance costs. Another trend is the development of smart fuel filters equipped with sensors that monitor filter health in real-time, alerting drivers before any potential clogging occurs and ensuring the longevity and reliability of engine systems.

**Tip:** Regularly replacing fuel filters according to manufacturer recommendations can improve fuel efficiency and protect your engine from soot and debris, which can cause significant damage over time. Additionally, consider upgrading to newer filter technologies that promise enhanced performance and lower emissions to keep your vehicle ahead in the evolving automotive landscape.

Impact of Advanced Fuel Filtration on Engine Performance and Longevity

The impact of advanced fuel filtration on engine performance and longevity is profound, especially across various industries. High-quality fuel filters significantly enhance the efficiency of engines by removing contaminants that can cause wear and tear. When clean fuel enters the combustion chamber, the engine operates more smoothly, leading to improved power output and fuel efficiency. This not only maximizes performance but also extends the lifespan of the engine, saving companies on costly repairs and downtime.

**Tip:** Regularly check and replace fuel filters according to the manufacturer's recommendations to prevent engine damage. Delaying this maintenance can lead to blockages that restrict fuel flow, negatively affecting engine performance.

Furthermore, innovative fuel filter designs utilize advanced materials and technology to capture even the smallest particles, ensuring that engines run cleaner. In industries where heavy machinery operates under extreme conditions, the right fuel filtration can mean the difference between reliable performance and unexpected failures.

**Tip:** Consider investing in fuel filters that are tailored to specific environments and fuel types, as this customization can significantly enhance filtration efficiency and engine protection.

Best Practices for Fuel Filter Applications in Marine and Aviation Industries

In the marine and aviation industries, the importance of high-quality fuel filters cannot be overstated. According to a report by Frost & Sullivan, the global demand for fuel filtration systems is expected to grow significantly, reaching approximately USD 6 billion by 2025. In these sectors, fuel filters serve as a critical line of defense against contaminants that can lead to engine failures and safety risks. Best practices for fuel filter applications include the use of multi-stage filtration systems, which effectively remove particles down to 1 micron, ensuring cleaner fuel delivery.

For marine applications, recent data from the International Maritime Organization (IMO) illustrates that a significant portion of engine failures can be attributed to fuel contamination. Implementing advanced filtration solutions, such as polymeric filters with enhanced dirt-holding capacity, can significantly reduce maintenance costs and enhance engine performance. Similarly, in the aviation sector, adherence to strict standards set by the Federal Aviation Administration (FAA) necessitates the use of reliable fuel filtration systems. Air travel, growing at a rate of 4% annually according to the International Air Transport Association (IATA), emphasizes the critical need for innovative fuel filter designs that can support this expanding demand while ensuring safety and efficiency.

Innovative Applications of Best Fuel Filters in Marine and Aviation Industries

The Role of Fuel Filters in Ensuring Compliance with Environmental Regulations

In today's industrial landscape, fuel filters play a crucial role in meeting environmental regulations. According to a report by the Environmental Protection Agency (EPA), the transportation and industrial sectors are responsible for a significant portion of air pollution, with more than 29% of greenhouse gas emissions attributed to fuel combustion. By effectively removing contaminants and particulate matter from fuel, high-quality fuel filters not only enhance engine performance but also significantly reduce harmful emissions, aiding compliance with the stringent standards set by regulatory bodies.

The adoption of innovative fuel filtration technologies has been pivotal in various industries, including automotive, aviation, and marine sectors. A study by the International Council on Clean Transportation (ICCT) found that advanced filtration systems can lower particulate emissions by up to 50%. This reduction is essential, given that particulate matter can lead to serious health issues and environmental damage. Furthermore, with tightening regulations in regions such as the European Union and California, ensuring proper fuel filtration is now more critical than ever for companies looking to avoid fines and maintain sustainable operations. The integration of best fuel filter practices thus not only supports regulatory compliance but also contributes to a greener planet by mitigating the overall environmental impact of fuel usage.

Innovative Applications of Best Fuel Filters in Diverse Industries - The Role of Fuel Filters in Ensuring Compliance with Environmental Regulations

| Industry | Application | Compliance Standard | Benefit |

|---|---|---|---|

| Automotive | Fuel cleanliness for engines | EPA Standards | Improved fuel efficiency and reduced emissions |

| Marine | Prevention of fuel contamination | IMO MARPOL | Enhanced vessel performance |

| Aerospace | Fuel system defect prevention | FAA Regulations | Safety and reliability in flight |

| Power Generation | Maintenance of fuel integrity | ISO 14001 | Reduced operational costs |

| Construction | Fuel supply for heavy machinery | OSHA Guidelines | Prolonged equipment life |

Economic Benefits of High-Quality Fuel Filters for Industrial Equipment Efficiency

High-quality fuel filters play a crucial role in maximizing the efficiency of industrial equipment. According to a study by the National Renewable Energy Laboratory, proper fuel filtration can enhance system efficiency by up to 10%, directly impacting operational costs. In industries where heavy machinery operates continuously, even a minor improvement in fuel efficiency translates to substantial economic benefits. The reduction in fuel consumption can not only lower operational expenses but also minimize emissions, aligning with global sustainability goals.

Tip: Regularly check and maintain fuel filters to prevent clogging, which can cause engine performance issues and increased operational costs. A well-maintained fuel filter can extend equipment life and reduce the frequency of costly repairs.

Investing in top-tier fuel filters can yield long-term savings. A report from the American Petroleum Institute indicates that facilities using high-quality filtration systems experience fewer breakdowns and lower fuel consumption rates. As companies seek to enhance their bottom line and environmental compliance, integrating advanced fuel filtration technology is becoming a strategic necessity.

Tip: When selecting fuel filters, consider those with higher dirt-holding capacity and longer service intervals. This can decrease downtime and improve productivity while ensuring reliable fuel delivery to your equipment.