2026 Top Uses of Stainless Steel Woven Wire Mesh?

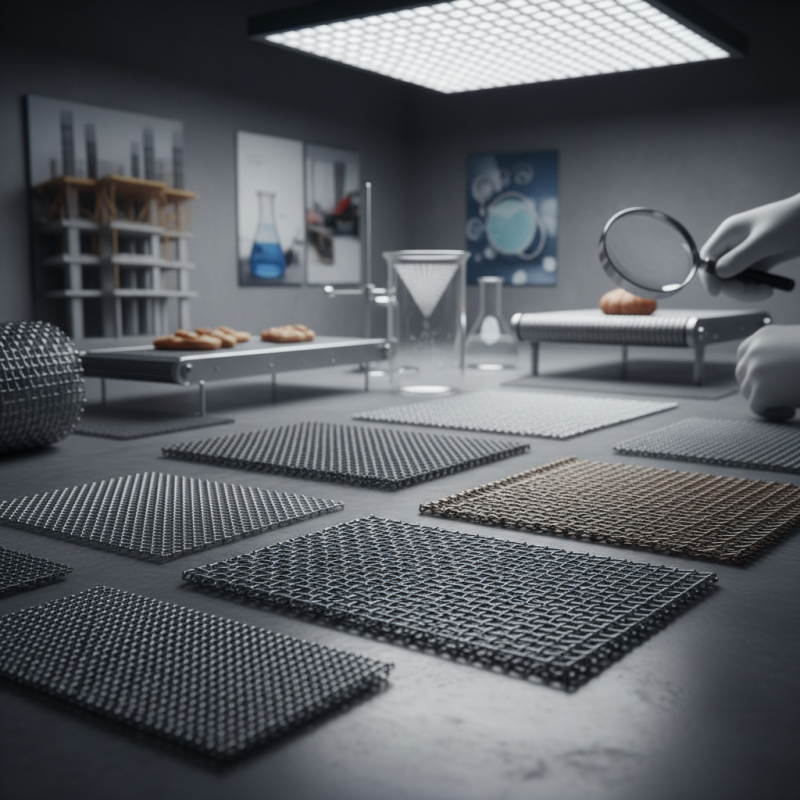

As industries evolve, the role of stainless steel woven wire mesh is becoming increasingly vital. This versatile material is employed in various applications, from filtration and separation to architectural design and safety. According to a recent market report by Research and Markets, the global woven wire mesh market is projected to reach $3.5 billion by 2026. This growth highlights the rising demand for stainless steel woven wire mesh across multiple sectors.

Industry expert Dr. Emily Chen states, "The unique properties of stainless steel woven wire mesh make it indispensable in modern engineering." This sentiment echoes throughout sectors such as food processing, pharmaceuticals, and construction. The mesh is valued for its strength, durability, and resistance to corrosion, yet not all applications leverage its full potential.

Despite its advantages, some businesses struggle to select the right mesh type. Misunderstandings about wire thickness and weave patterns can lead to inefficient designs. This reveals a need for better education on product specifications within the industry. Enhancing knowledge about stainless steel woven wire mesh is essential for maximizing its benefits and addressing challenges.

Top Applications of Stainless Steel Woven Wire Mesh in Industries

Stainless steel woven wire mesh is versatile and widely used across various industries. Its durability and resistance to corrosion make it ideal for applications in food processing. Many facilities utilize this mesh for sieving and filtration. When properly maintained, it can last for years. However, regular inspections are necessary to ensure it remains effective.

In the construction industry, stainless steel woven wire mesh is essential for reinforcing concrete. It provides structural integrity to buildings and other infrastructures. Yet, the mesh must be installed correctly to avoid future issues. Overlapping and misalignment can weaken the structure. Proper training for workers is critical to achieve the best results.

Additionally, this mesh is prevalent in the automotive industry. It is often used in exhaust systems and air filters. The goal is to improve performance and ensure safety. However, some manufacturers face challenges regarding mesh specifications. Inconsistencies can lead to performance issues in vehicles. Rigorous quality control processes are necessary to mitigate these problems.

2026 Top Uses of Stainless Steel Woven Wire Mesh

Advantages of Using Stainless Steel Woven Wire Mesh for Filtration

Stainless steel woven wire mesh is a versatile material, widely used in filtration applications. This mesh offers significant advantages due to its unique properties. It is resistant to corrosion and extremely durable. Reports indicate that stainless steel meshes can last for decades, even in harsh environments. This longevity makes them a preferred choice in industries like food processing and pharmaceuticals.

One of the key benefits of using stainless steel woven wire mesh is its ability to maintain structural integrity. Unlike other materials, it does not degrade easily. This ensures consistent filtration performance. The mesh can filter particles of various sizes, from small dust to larger debris. Studies show that stainless steel filtration systems can achieve above 90% efficiency in particle removal.

Tips: Always choose the right weave pattern for your specific needs. A tighter weave captures smaller particles, while a looser weave allows for higher flow rates. Consider the balance between flow rate and filtration efficiency when selecting your mesh.

Though stainless steel is a superior choice, it is essential to think about cost. Initial investment may be higher than alternatives. However, this often leads to savings in maintenance and replacement costs over time. Reflect on the long-term benefits before making a decision.

Role of Stainless Steel Woven Wire Mesh in Construction and Architecture

Stainless steel woven wire mesh plays a significant role in construction and architecture. Its durability and versatility make it an excellent choice for various applications. Architects often use it for facades, providing both aesthetic appeal and practicality. The mesh allows for ventilation while maintaining an eye-catching design. It is also popular for partitions, creating spaces without sacrificing openness.

When selecting stainless steel mesh, consider the weave pattern and thickness. The right choices can enhance strength and aesthetic value. Periodically review your design needs. Sometimes, a simple change in mesh size can transform the overall look of a project. Avoid following trends blindly; focus on what complements your design vision.

Installation can be tricky. Ensure precise measurements are taken before cutting. A minor error can lead to significant issues later. Use proper tools to avoid mesh damage during installation. Consult with experts if you're uncertain about techniques. Remember, a well-installed mesh can elevate a structure’s visual impact tremendously.

Innovative Uses of Stainless Steel Woven Wire Mesh in Design and Art

Stainless steel woven wire mesh has sparked significant interest in design and art. This innovative material blends durability with aesthetic appeal, offering artists unique opportunities. According to a recent industry report, the market for stainless steel mesh in architectural applications is forecasted to grow by 6.5% annually, reaching $1.5 billion by 2026.

In art installations, stainless steel mesh creates breathtaking visual effects. Artists utilize its intricate patterns to play with light and shadow. For instance, the mesh can be shaped into organic forms, evoking natural elements. Sculptures made from this material are both sturdy and captivating. However, there are challenges. The material's reflective quality can sometimes overshadow subtle details. Artists must navigate this fine balance.

Moreover, architects embrace stainless steel mesh for innovative facades. This trend enhances building aesthetics while ensuring structural integrity. The mesh serves functional purposes too, like filtration and safety. Despite its advantages, installation issues can arise. Misalignment might impact the final visual effect, necessitating careful planning. The journey to mastering this medium is ongoing, often requiring re-evaluation and adjustment.

2026 Top Uses of Stainless Steel Woven Wire Mesh

| Use Case | Description | Benefits | Common Applications |

|---|---|---|---|

| Architectural Features | Used in building facades, railings, and screens. | Aesthetically pleasing, durable, and corrosion-resistant. | Commercial buildings, bridges. |

| Art Installations | Used in sculptures and modern art pieces. | Versatile, can create intricate designs. | Museums, galleries, public art displays. |

| Industrial Filters | Used in filtration systems for various industries. | High durability and easy to clean. | Water treatment, chemical processing. |

| Safety Screens | Installed in windows and doors for safety. | Enhances security while allowing visibility. | Residential and commercial properties. |

| Kitchen Utensils | Used in cooking tools and equipment. | Non-reactive and durable for food safety. | Restaurants, homes. |

Environmental Benefits of Stainless Steel Woven Wire Mesh in Sustainability

Stainless steel woven wire mesh offers significant environmental benefits that align with sustainability goals. One major advantage is its durability. This material resists corrosion and wear, reducing the need for frequent replacements. Less frequent replacement leads to decreased waste and lower resource consumption. Additionally, stainless steel is 100% recyclable. This means that at the end of its life cycle, the mesh can be repurposed, minimizing landfill contributions.

When using stainless steel woven wire mesh, consider how to optimize its life span. Regular cleaning can help maintain its appearance and functionality. It's also essential to choose the correct type for each application, ensuring it meets the specific needs of your project. Sometimes, designs need to be adjusted to suit the environment better, which may seem challenging but can yield long-term benefits.

Moreover, some may overlook the importance of sourcing. Choosing locally produced materials can cut transportation emissions. It’s also worth reflecting on the design choices that prioritize longevity over short-term aesthetics. Such considerations can foster a more sustainable mindset in the long run while enhancing the utility of the woven material.